Textile Restoration

Textile Restoration

Counter what is commonly expected from the phrase dry cleaning today, dry cleaning in Preservation and Conservation refers to a cleaning process that is entirely mechanical, without water, chemicals, or cleaners.

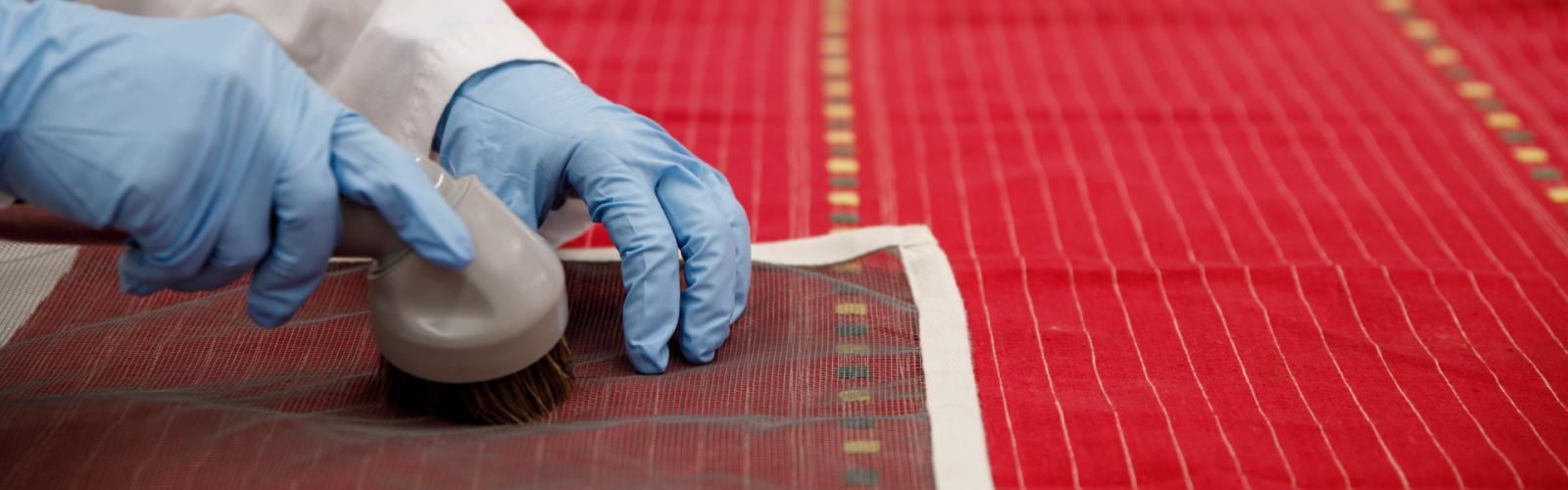

Surface cleaning involves mechanical removal of lint, dust, and other particulate matters. This is usually achieved by brushing with a very soft brush, for sturdier items, vacuuming is effective.

Usually all but the most fragile textiles can withstand vacuuming if the appropriate special equipment is used, and with most vacuum cleaners the amount of suction can be controlled usually by opening the vents or using a low powered setting.

It is important to make sure that all attachments and brushes touching the textiles are clean to prevent the transfer of dirt and debris. It may also be helpful to place a piece of screening on top of fragile textiles during vacuuming, to protect the textile from abrasion or strong suction.

Good practice in preparation for vacuuming is to lay the textile flat on a clean and smooth surface, vacuuming very carefully moving in a regular pattern to help track the areas that have been covered. If there is a nap or pile in the fabric, vacuum in the direction of the pile to minimize destress to the textile and maximize effectiveness of the vacuuming. It is also important to make sure to vacuum the front and back.

If the textile must be rolled, clean the back as you go to avoid transferring dirt from one side to the other.

How frequently something should be vacuumed will depend on the condition of the textile and how it is used or exhibited. Textiles that are displayed horizontally such as carpeting will require more frequent maintenance however textiles that have brittle fibers or delicate surface features such as formal dresses with beading or applique work may not be able to tolerate frequent vacuuming if any at all.

The first step in the process is always determining the best method to achieve the desired end goal, with the minimal risk to the textile.

Once the best cleaning process has been determined, the piece should be prepared for washing

Usually, this involves vacuuming to remove any surface dirt, linings and backings should also be removed, vacuumed, and washed separately.This is not only to prevent color bleeding, but to avoid trapping dirt between the layers, which may cause discoloration from the inside.

The solution should be placed in a container large enough for the textile to lie flat in. For large pieces, it may be necessary to construct a temporary basin outside or in a large room. If a smaller basin is used, it should be of ceramic, stainless steel or a stable plastic to prevent the material from interfering with the process.

The textile should be washed in a flat, fully supported position, preferably sandwiched between two screens.

The screen-encased textile is lowered into the solution. The textile can then be washed by pressing a soft sponge directly down onto the fibers. The sponge should not be rubbed, as this will cause unnecessary abrasion at a moment when the textile is already weak from the water. The textile may be submerged for no more than an hour depending on its materials and general stability and should be rinsed at least four times after it is cleaned. The final rinse should always be with distilled water, as hard water can leave mineral traces.

An issue with a lot of elaborate historical textiles is that many historical garments were made with metallic threads such as silver, gold, or copper. These are very difficult to clean as any method of cleaning metal threads is often detrimental to the other fibers that are present, either deteriorating them outright, causing loss of dye or even issues with removing the gilding if the thread was plated, and not a solid wire.

Mechanical cleaning removes the plating if the threads are made of silver or gilt. Chemical or electrolytic techniques can be used, but the immersion process may damage the fibers and dissolve any dye. These problems have led conservators to look for other cleaning methods including laser techniques, which seem promising, but many metals absorb relatively strongly at ultraviolet wavelengths.

Therefore, irradiation at ultraviolet and infrared wavelengths might lead to heating of the metal threads which can cause a problem when a composite made of textile and metal is considered.

Laser cleaning of metal threads does appear to be possible, but side effects include modifications of the appearance or textures of the materials in question. There may be an option in the future of mixing laser cleaning with other forms of cleaning methods to try and achieve a more optimal result but that will be on a case-by-case basis.